Ever-power Agricultural Machinery Spare Parts HL008

(0

đánh giá)

Ước tính thời gian vận chuyển:

3 Ngày

Sản phẩm nội bộ

Giá bán

$316.61

/kg

Chia sẻ

Sản phẩm bán chạy nhất

Đánh giá & Xếp hạng

0

trong số 5.0

(0

đánh giá)

Chưa có nhận xét nào cho sản phẩm này.

Brief Details

Condition:

New

Guarantee:

1.5 Years

Applicable Industries:

Machinery Repair Shops, Food & Beverage Plants, Farms, Home Use, Energy & Mining, center pivot irrigation system

Weight (KG):

50 KG

Showroom Tri:

Do not have

Video Call-Check:

Provide

Machine Test Report:

Provide

Marketing Type:

New Products 2020

Type:

Axis

Use:

Practice

Brand:

ever-power

Input speed:

<1500r/min

Body material:

Cast iron

Input style:

solid shaft

Output style:

Hub connecting flange

Other characteristics:

irrigation machine gearbox

Shaft orientation:

90 degrees vertically

Fixed way:

flange

Gear type:

Worm gear

After Warranty Service:

Online support

Product Description

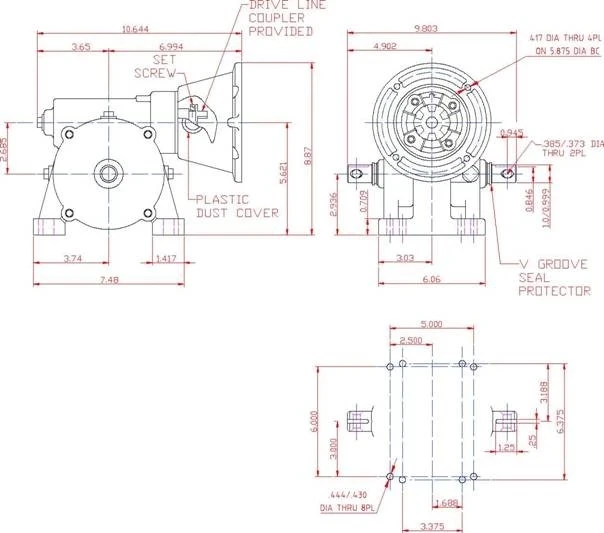

Farm center pivot gearbox irrigation irrigation drive system wheel system gearbox for valley pivot replacement zimmatic UMC

|

Product Catalog

|

Special hydraulic gearbox

|

|

Input speed

|

<1500r/min

|

|

Body material

|

Cast iron

|

|

Style Input

|

Solid shaft

|

|

Style output

|

Flange connection hub

|

|

Other

Features |

Watering for gearboxes

|

|

Orientation axis

|

90 degrees vertically

|

|

Device Type

|

Gearbox worm

|

|

How to fix

|

Flange

|

|

Proportion

|

50:1

|

|

Torque output

|

Standard

|

|

Other parameters

|

Can replace UMC, durst, zimmatic, valley gearbox

|

Tell you what hydraulic gearbox is

The gearbox for valley shaft is a mechanical device installed in the pivot center of the irrigation system to help drive the movement of the system's pivot points. It is an important part of the irrigation system and consists of gears, shafts, bearings, seals, and housing.

The gearbox helps transfer power from the system's electric motor to the wheels or tires that move the pivot points of the

irrigation system. As the electric motor operates, the gearbox uses gears and shafts to reduce the rotational speed and increase the torque delivered to the wheels or tires. This helps the wheels or tires move the pivot center of the irrigation system at the required speed to apply water to the plants when needed.

The gearbox for valley shaft comes in different sizes and gear ratios to suit the specific requirements of different irrigation systems. Regular maintenance and inspection of the gearboxes is essential to ensure proper operation and to avoid costly system downtime during the critical long-term process of crop growth.

The gearbox helps transfer power from the system's electric motor to the wheels or tires that move the pivot points of the

irrigation system. As the electric motor operates, the gearbox uses gears and shafts to reduce the rotational speed and increase the torque delivered to the wheels or tires. This helps the wheels or tires move the pivot center of the irrigation system at the required speed to apply water to the plants when needed.

The gearbox for valley shaft comes in different sizes and gear ratios to suit the specific requirements of different irrigation systems. Regular maintenance and inspection of the gearboxes is essential to ensure proper operation and to avoid costly system downtime during the critical long-term process of crop growth.

Input and Output Bearings: American made and case hardened; industries highest load rating for longer life

Gearbox housing: More material in high-stress areas to handle extreme operating conditions

Bronze Bull gear option: Provides additional load capacity with hardened Worm steel for extreme operating conditions or extended life under less severe conditions

Bronze Bull gear option: Provides additional load capacity with hardened Worm steel for extreme operating conditions or extended life under less severe conditions

Large-capacity rubber diaphragm: Expands with heat and pressure to minimize condensation.

Inlet and outlet bearings: Fine made and case hardened to provide the highest quality and highest load rating available in the industry.

Worm gear: High-strength ductile iron provides significantly longer wear life than steel when combined with a cast iron bull gear.

Tooth design: Industry exclusive 25° tooth angle Provides 40% longer life and better reliability under difficult conditions compared to conventional 14 1/2° tooth designs.

Largest bull gear collar and keyway: For strength in critical load-bearing areas.

Expansion chamber: Cap Made of corrosion-resistant cast aluminum; rubber diaphragm allows oil to expand and contract during operation. Vented cap prevents pressure buildup and prevents seals from leaking.

Threaded endcap: Allows for precise bearing preload to increase bearing life.

50:1 Gear Ratio: Fully concave tooth design keeps oil between gear engagement.

Gears: High-strength cast iron provides the highest load capacity and longest life in the industry. Optional Bronze gears are available for extreme conditions.

Multi-Viscosity Gear Oil: Exceeds 85W140 GL5 oil for long-lasting gear bearing under extreme load conditions.

Inlet and outlet bearings: Fine made and case hardened to provide the highest quality and highest load rating available in the industry.

Worm gear: High-strength ductile iron provides significantly longer wear life than steel when combined with a cast iron bull gear.

Tooth design: Industry exclusive 25° tooth angle Provides 40% longer life and better reliability under difficult conditions compared to conventional 14 1/2° tooth designs.

Largest bull gear collar and keyway: For strength in critical load-bearing areas.

Expansion chamber: Cap Made of corrosion-resistant cast aluminum; rubber diaphragm allows oil to expand and contract during operation. Vented cap prevents pressure buildup and prevents seals from leaking.

Threaded endcap: Allows for precise bearing preload to increase bearing life.

50:1 Gear Ratio: Fully concave tooth design keeps oil between gear engagement.

Gears: High-strength cast iron provides the highest load capacity and longest life in the industry. Optional Bronze gears are available for extreme conditions.

Multi-Viscosity Gear Oil: Exceeds 85W140 GL5 oil for long-lasting gear bearing under extreme load conditions.

Application

How to replace old center pivot gearbox

Replacing the old center pivot gearbox requires certain mechanical and electrical skills, as well as appropriate tools. The following are the basic steps to replace the old center pivot gearbox: 1. First, turn off all the power and water sources of the system and stop the irrigation system. 2. To remove the old gearbox, it is often necessary to remove the wheels, shafts and other drive parts. At the same time, attention must be paid to prevent water from overflowing, and relevant pipes should be blocked. 3. Use appropriate tools to disassemble the old gearbox, disassemble and retain all spare parts for future repair or replacement. 4. Install a new gearbox, which includes reinstalling the wheels, shafts and other drive components. During the installation, ensure that the seals are intact and firmly installed. 5. And calibrate and test the new gearbox to ensure it works properly. The electrical system can be turned on, and the center pivot system can be operated via remote control to ensure the correct operation of the new gearbox and coordination with other components of the system. 6. Finally, check all the pipes of the system to ensure that they are correctly reassembled and free of leaks. 7. Please note that the steps are only the basic ideas of replacing the center pivot gearbox. The specific steps and requirements may vary depending on the equipment model, working manufacturer, production date and other factors. It is recommended to read the relevant documents, manuals and instructions carefully before operation, or seek professional maintenance and installation services. In addition, in order to ensure the health of the earth, it is necessary to follow the correct methods of disposal and recycling of old equipment

Related Products

Ever-Electric Group Co., Ltd. is expert in making all kinds of mechanical transmission and hydraulic transmission such as: Planetary gearbox, Worm gearbox, In-Line helical gear speed gearbox, Parallel shaft helical gear gearbox, Helical bevel gearbox, Helical worm gear gearbox, Agricultural gearbox, Tractor gearbox, Automatic gearbox, PTO Drive shaft, Special reducer & related gear components and other related products,, sprockets, hydraulic system, vacuum pump, fluid coupling, gear racks, chains, timing pulley, udl speed variators, V pulley, hydraulic cylinder, gear pump, screw air compressor, shaft collar low backlash worm gearbox and so on. Moreover, we can produce customized variators, gear motors, electric motors and other hydraulic products according to customers' drawings.

Certificate

Product packaging

Sản phẩm thường mua

Thắc mắc về sản phẩm (0)

Đăng nhập Hoặc là Đăng kýđể gửi câu hỏi của bạn cho người bán

Những câu hỏi khác

Chưa có ai hỏi người bán

Sản phẩm bán chạy nhất

![[Best Seller] Lenovo IdeaCentre AIO 3 24IAP7 | F0GH0006ST | 23.8" FHD (1920x1080) | Intel Core i5-1240P | 16GB RAM | 256GB SSD + 1TB HDD | Intel Iris Xe Graphics | Win11 Home | 3Y Onsite Warranty](https://www.usadropshiping-aliex.com/public/uploads/all/dJ6UGaUETQa2LQgkfIpVgMlHV7zHzjEwZj5eizg2.jpeg)

![[6 Flavors] Lilo Premium Baby Food Powder Bottle 50G | Ikan Bilis / Mushroom / Scallop / White Bait / Kombu | Baby Food Powder / Baby Food](https://www.usadropshiping-aliex.com/public/uploads/all/ueYx1yLgcAyfW5913xXjBfsdX5o01VGrDavO0AVx.jpeg)